No products in the cart.

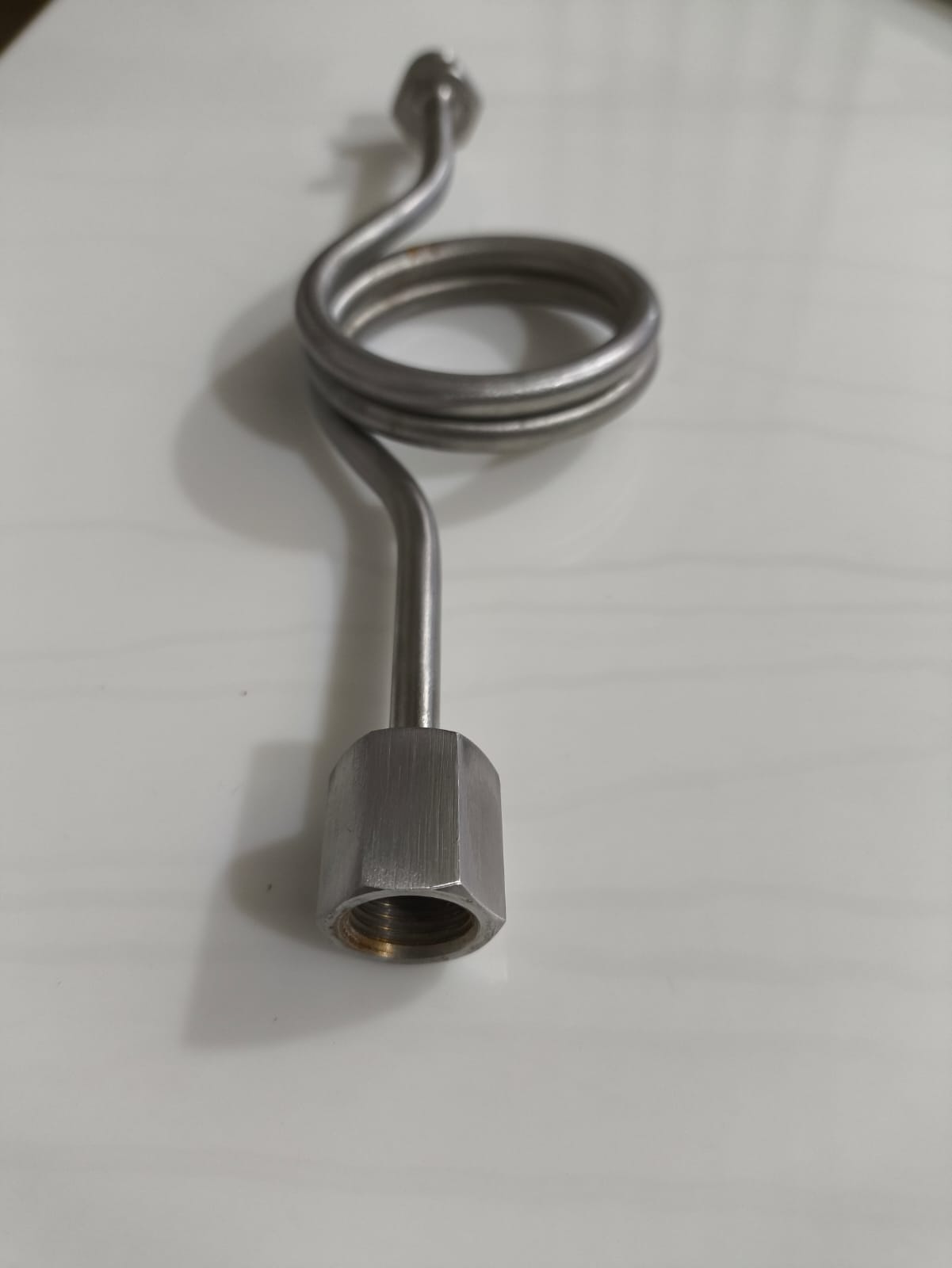

ss Syphon Double Q , Size: 1/4 BSP

In Stock

In Stock

Category: Process Instruments

Tags: Q Syphone, ss Syphone, Syphone 1/4 BSP Male Female

ss Syphone Double Q , Size: 1/4 BSP

Connection: 1/4 BSP Male x 1/4 BSP Female

Description

ss Syphon Double Q , Size: 1/4 BSP

Connection: 1/4 BSP Male x 1/4 BSP Female

Be the first to review “ss Syphon Double Q , Size: 1/4 BSP” Cancel reply

Related products

Specifications

No. of Channels : One , speed : 20 to 200 RPM, Flow rate : 1.6 to 16 Lit/min

Tubing : 20 mm I.D. with 4 mm wall thickness

End Connection : 3/4” TC(Tc 50mm)

M.O.C. of the Pump Head

Outer ARM : Anodized Aluminum

ARM Cover : Transparent Polycarbonate

Rotor : S.S.304

Rollers : Carbon filled Nylon

Enclosure : S.S.304

Motor : 3 phase, 0.5 H.P. geared AC motor

Differential Pressure : Up to 2 Kg/Sq.cm Supply : 230v, 50Hz, Single phase AC supply, 370 Watt

Dimension : 240 x 400 x 620 mm (H x W x D)

Weight : 25 Kgs .(Approx.)

Controls

- Single phase input three phase output AC drive (VFD) with seven segment LED Digital display for speed control and direction reversal functions.

Application: The Sterializable pH Sensor with Controller is perfect for maintaining optimal pH levels in various industrial applications, including:

- Fermenters: Ensure precise pH control to optimize fermentation processes in the food and beverage industry.

- Bioreactors: Provide accurate pH monitoring for biological reactions in biotech and pharmaceutical manufacturing.

- Chemical Processing: Deliver reliable pH measurement for various chemical reactions and processes.

- Biofertilizer Production: Optimize production environments with precise pH regulation.

- Pharmaceutical Manufacturing: Ensure safe and consistent pH levels in pharmaceutical production processes.

- Dairy Processing: Maintain optimal pH conditions for various dairy processing applications.

- Biotech Operations: Support a wide range of biotech processes with reliable pH monitoring and control.

Features:

- Material: Durable, clear acrylic body for easy readability and chemical resistance.

- Flow Rate: Measures flow rates up to 1000 liters per minute (LPM).

- Precision: High accuracy for consistent and reliable flow measurements.

- Easy Installation: Simple to install and integrate into various fermentation systems.

- Scales and Markings: Clear, easy-to-read scales for quick monitoring.

- Versatile Use: Suitable for a range of fluids used in fermentation processes.

- Compact Design: Space-saving design ideal for various setups.

- Low Maintenance: Minimal maintenance required due to robust construction.

Pressure Transmitter MEAS

Model:M3256-000002-004BG

Pressure Range: 0-4 BARG

Supply: 9-30 VDC

Output: 4-20 mA

Port Size: 1/4-19BSPP

Application: The Denforce KP 35 Diaphragm Type Pressure Switch is ideal for use in a broad range of industrial applications, including:

- Fermenters: Maintain precise pressure control for optimal fermentation processes in the food and beverage industry.

- Bioreactors: Ensure accurate pressure monitoring for biological reactions in biotech and pharmaceutical manufacturing.

- Chemical Processing: Provide reliable pressure control for chemical reactions and processes.

- Biofertilizer Production: Optimize the production environment with accurate pressure regulation.

- Pharmaceutical Manufacturing: Ensure safe and consistent pressure levels in pharmaceutical production processes.

- Dairy Processing: Maintain optimal pressure conditions for various dairy processing applications.

- Biotech Operations: Support a wide range of biotech processes with reliable pressure monitoring and control.

SS Pressure Gauge (2.5 inch Dial- 4bar) ( 1/4 inch Thread Connection)

Features:

- Stainless Steel Construction: Built with high-grade stainless steel for superior durability and corrosion resistance.

- Gel-Filled: The gel-filled mechanism reduces the impact of vibrations and pulsations for stable readings.

- 2.5-Inch Dial: Easy-to-read dial with clear markings for quick and accurate pressure monitoring.

- 4 Bar Pressure Range: Suitable for a variety of fermentation processes requiring precise pressure control.

- Hygienic Design: Easy to clean, making it perfect for the food and beverage industry.

- Versatile Compatibility: Designed to fit various fermenter configurations.

- Robust Build: Engineered to withstand the rigors of industrial environments.

Reviews

There are no reviews yet.