Showing all 11 resultsSorted by latest

RTD PT-100 Temperature Sensor

Why Choose Our PT100 Temperature Sensor – Smart Choice for Process Accuracy

Selecting the right temperature sensor is critical for process efficiency, product quality, and regulatory compliance. Our TC End PT100 Temperature Sensor is designed to offer unmatched performance, making it the preferred choice for industrial buyers. As a trusted pt100 Temperature Sensor Manufacturer, we ensure precision, durability, and consistency in every unit.

Manufacturers in Rajkot, Bhavnagar, and Jamnagar choose our Tri Clover End pt100 Temperature Sensor With Head for its hygienic design and accurate response. The Tc End Temperature Sensor Size 8mm Dia x 100mm Length allows easy integration into standard TC ports, eliminating the need for adapters or modifications.

Industrial zones in Jaipur, Udaipur, and Kota benefit from the sensor’s low maintenance requirements and long operational life. The SS construction ensures resistance to aggressive cleaning chemicals and high-temperature sterilization. As dependable TC End Temperature Sensor Suppliers, we focus on providing sensors that perform reliably in real-world conditions.

Pharmaceutical units in Kanpur, Lucknow, and Varanasi rely on this sensor for batch consistency and compliance with GMP standards. The sensor’s accuracy helps maintain critical process parameters, reducing batch rejection and improving overall productivity.

From biotech research centers in Patna, Ranchi, and Jamshedpur to large-scale manufacturing plants in Kolkata, Howrah, and Durgapur, our sensors support a wide range of applications. Recognized as the Best Quality pt100 Sensor For Pharma and Biotech Machinery, this product delivers long-term value through precision, reliability, and competitive pricing.

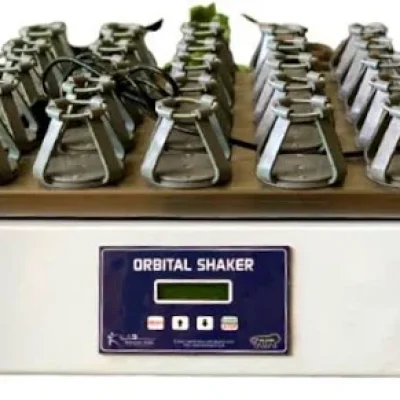

UMA PHARMATECH MACHINERY is a top-tier Laboratory Shaker Manufacturer offering precision-built Orbital Shakers and Rotary Shakers designed to hold 500ml - 16 flasks with smooth and consistent motion. Our laboratory shakers are widely used in microbiology, biotechnology, pharmaceutical, and fermentation labs for mixing, culturing, and incubation processes. As reliable Orbital Shaker Suppliers and Rotary Shaker Manufacturers, we provide robust, vibration-free equipment with adjustable speed and digital control. Trusted across research labs and industrial facilities, our laboratory shakers ensure long operational life, accurate RPM, and optimal temperature resistance, making them an ideal choice for scientific laboratories across India.

Best Orbital Shaker Manufacturer for Laboratory and Industrial Use

When research labs and industrial production units in Ahmedabad, Hyderabad, and Pune look for a trusted Orbital Shaker Manufacturer, they prioritize durability, precise speed control, and long-lasting performance. UMA PHARMATECH MACHINERY is one of the leading names in supplying premium-quality Orbital Shakers designed for laboratory research, pharmaceutical testing, and chemical mixing. Laboratories in Mumbai and Bengaluru prefer Laboratory Rotary Shaker systems that ensure smooth and consistent agitation for cell culture, microbial growth, and enzyme activity. Choosing UMA PHARMATECH MACHINERY guarantees robust performance for both small and large-volume sample mixing.

Reliable Orbital Shaker Suppliers for Pharmaceutical and Biotech Labs

In cities like Chennai, Lucknow, and Kolkata, pharmaceutical companies and biotech labs are consistently searching for reliable Orbital Shaker Suppliers to enhance their R&D activities. UMA PHARMATECH MACHINERY supplies Laboratory Rotary Shakers with advanced features like digital RPM control, timer settings, and platform customization for various flask capacities. Research centers in Gurgaon and Noida prefer UMA PHARMATECH MACHINERY for their dependable after-sales support and consistent supply of laboratory equipment. Their Orbital Shakers are suitable for bacterial culture, protein expression, and biochemical analysis in pharmaceutical and agriculture research sectors.

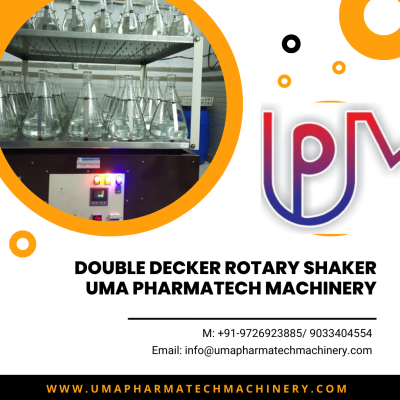

| Description | Qty | Amount(INR) |

| Double Decker Rotary Flask Shaker (5L- 50 Flask) Extended Platform Size( 1250 x 1250) Powered by continuous duty, variable speed self cooled Ac Motor with adjustable Orbital speed from 50 to 140 RPM. 5000 ml- 25 Nos – Bottom 5000 ml- 25 Nos - Top · Top Sheet Made Of Colour Coated Mild Steel Material For Flask Mounting · Base Structure Made Of Mild Steel Material Painted With Red Oxide · Motor: Ac Motor · Rotate With Eccentric Mechanism · VFD For Speed Controlling · Outer Cover Made Of Powder Coated Mild Steel Material · Fixed Eccentricity Stroke 30MM · Holding Clamp Comes With Shaker 50 Nos | 1 NOS | Amount Without Tax & Transportation |

- Fermenters: Ensure precise DO control to optimize fermentation processes in the food and beverage industry.

- Bioreactors: Provide accurate DO monitoring for biological reactions in biotech and pharmaceutical manufacturing.

- Chemical Processing: Deliver reliable DO measurement for various chemical reactions and processes.

- Biofertilizer Production: Optimize production environments with precise DO regulation.

- Pharmaceutical Manufacturing: Ensure safe and consistent DO levels in pharmaceutical production processes.

- Dairy Processing: Maintain optimal DO conditions for various dairy processing applications.

- Biotech Operations: Support a wide range of biotech processes with reliable DO monitoring and control.

- Fermenters: Ensure precise pH control to optimize fermentation processes in the food and beverage industry.

- Bioreactors: Provide accurate pH monitoring for biological reactions in biotech and pharmaceutical manufacturing.

- Chemical Processing: Deliver reliable pH measurement for various chemical reactions and processes.

- Biofertilizer Production: Optimize production environments with precise pH regulation.

- Pharmaceutical Manufacturing: Ensure safe and consistent pH levels in pharmaceutical production processes.

- Dairy Processing: Maintain optimal pH conditions for various dairy processing applications.

- Biotech Operations: Support a wide range of biotech processes with reliable pH monitoring and control.

- Fermenters: Maintain precise pressure control for optimal fermentation processes in the food and beverage industry.

- Bioreactors: Ensure accurate pressure monitoring for biological reactions in biotech and pharmaceutical manufacturing.

- Chemical Processing: Provide reliable pressure control for chemical reactions and processes.

- Biofertilizer Production: Optimize the production environment with accurate pressure regulation.

- Pharmaceutical Manufacturing: Ensure safe and consistent pressure levels in pharmaceutical production processes.

- Dairy Processing: Maintain optimal pressure conditions for various dairy processing applications.

- Biotech Operations: Support a wide range of biotech processes with reliable pressure monitoring and control.