No products in the cart.

Shop and Save Big on Hottest Products

from ₹2500.00

Don't miss this special opportunity today.

Showing all 15 resultsSorted by latest

Specification of Fermenter

| Fermenter Vessel Details | ||||

| Working Volume(Litter) | 100L(Approx.) | |||

| Diameter(mm) | 400 | |||

| Straight Height(mm)(TL To TL) | 800 | |||

| shell(cylindrical) | 3 mm thk ss 316 | |||

| Jacket | 3 mm thk SS 304 | |||

| Top | Body Flange With Dish End | |||

| Bottom | Dished end( 10% torispherical) | |||

| leg | MS | |||

| Baffle Recommendation(Off Wall) | 4 Nos @ 90 Degree | |||

| manhole | No | |||

| Top Glass | 70mm(Vision 30mm) | |||

| Inner Finish | Mirror Finish | |||

| Outer finish | Matt Finish | |||

| Nozzles-Standard suitable -Tc 35mm x 19mm Connection | ||||

| Total Height | to be confirmed | |||

| Air Flow Control | Rotameter (100 LPM) | |||

| Scope of Buyer | Installation in scope of buyer (Electricity, Insulation, Water, Drain Line, Valves and Fittings and Clamp, Cooling Tower/ Overhead Tank Normal Water, Piping ) | |||

Why Choose Uma Pharmatech Machinery?

With a strong reputation in Surat and Rajkot, we offer customized fermenters that meet the specific needs of different industries. Our bioreactor systems are equipped with stainless steel construction, automatic control panels, and efficient agitation systems, ensuring superior performance and longevity. The demand for fermenter manufacturers in Gujarat is growing, and we are at the forefront of supplying top-notch equipment.

Uma Pharmatech Machinery is a trusted manufacturer and supplier of 20-litre laboratory fermenters in Gujarat, India. Designed for precision and durability, our fermenters cater to diverse research needs in cities like Ahmedabad, Surat, Vadodara, and more, ensuring reliable performance for biotechnology and industrial applications.

Application: The Serializable Dissolved Oxygen Sensor with Controller is perfect for maintaining optimal DO levels in various industrial applications, including:

- Fermenters: Ensure precise DO control to optimize fermentation processes in the food and beverage industry.

- Bioreactors: Provide accurate DO monitoring for biological reactions in biotech and pharmaceutical manufacturing.

- Chemical Processing: Deliver reliable DO measurement for various chemical reactions and processes.

- Biofertilizer Production: Optimize production environments with precise DO regulation.

- Pharmaceutical Manufacturing: Ensure safe and consistent DO levels in pharmaceutical production processes.

- Dairy Processing: Maintain optimal DO conditions for various dairy processing applications.

- Biotech Operations: Support a wide range of biotech processes with reliable DO monitoring and control.

Application: The Sterializable pH Sensor with Controller is perfect for maintaining optimal pH levels in various industrial applications, including:

- Fermenters: Ensure precise pH control to optimize fermentation processes in the food and beverage industry.

- Bioreactors: Provide accurate pH monitoring for biological reactions in biotech and pharmaceutical manufacturing.

- Chemical Processing: Deliver reliable pH measurement for various chemical reactions and processes.

- Biofertilizer Production: Optimize production environments with precise pH regulation.

- Pharmaceutical Manufacturing: Ensure safe and consistent pH levels in pharmaceutical production processes.

- Dairy Processing: Maintain optimal pH conditions for various dairy processing applications.

- Biotech Operations: Support a wide range of biotech processes with reliable pH monitoring and control.

Application: The Denforce KP 35 Diaphragm Type Pressure Switch is ideal for use in a broad range of industrial applications, including:

- Fermenters: Maintain precise pressure control for optimal fermentation processes in the food and beverage industry.

- Bioreactors: Ensure accurate pressure monitoring for biological reactions in biotech and pharmaceutical manufacturing.

- Chemical Processing: Provide reliable pressure control for chemical reactions and processes.

- Biofertilizer Production: Optimize the production environment with accurate pressure regulation.

- Pharmaceutical Manufacturing: Ensure safe and consistent pressure levels in pharmaceutical production processes.

- Dairy Processing: Maintain optimal pressure conditions for various dairy processing applications.

- Biotech Operations: Support a wide range of biotech processes with reliable pressure monitoring and control.

Application: The RTD PT-100 Temperature Sensor is essential for maintaining optimal temperature conditions in fermenters used in the food and beverage industry. Ideal for brewing beer, making wine, and other fermentation processes, this sensor provides precise temperature monitoring to ensure high-quality product outcomes. Its robust construction and reliable performance make it a trusted choice for industrial applications.

Meas Pressure Transmitter (0-4 Bar, 1/4 BSP, with Syphon) – 4-20mA Output for Fermenters

Application: The Meas Pressure Transmitter (0-4 Bar) is ideal for use in fermenters within the food and beverage industry. It ensures accurate pressure monitoring, which is crucial for producing high-quality beer, wine, and other fermented products. The integrated syphon provides added protection, making it perfect for applications involving high-temperature steam and condensate. Its reliable 4-20mA output ensures seamless integration with your existing control systems.

Features:

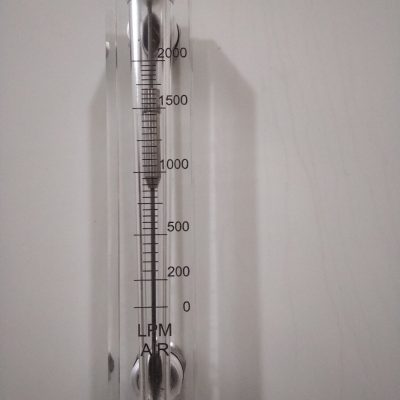

- Material: Durable, clear acrylic body for easy readability and chemical resistance.

- Flow Rate: Measures flow rates up to 2000 liters per minute (LPM).

- Precision: High accuracy for consistent and reliable flow measurements.

- Easy Installation: Simple to install and integrate into various fermentation systems.

- Scales and Markings: Clear, easy-to-read scales for quick monitoring.

- Versatile Use: Suitable for a range of fluids used in fermentation processes.

- Compact Design: Space-saving design ideal for various setups.

- Low Maintenance: Minimal maintenance required due to robust construction.

Features:

- Material: Durable, clear acrylic body for easy readability and chemical resistance.

- Flow Rate: Measures flow rates up to 1000 liters per minute (LPM).

- Precision: High accuracy for consistent and reliable flow measurements.

- Easy Installation: Simple to install and integrate into various fermentation systems.

- Scales and Markings: Clear, easy-to-read scales for quick monitoring.

- Versatile Use: Suitable for a range of fluids used in fermentation processes.

- Compact Design: Space-saving design ideal for various setups.

- Low Maintenance: Minimal maintenance required due to robust construction.

Features:

- Material: Durable, clear acrylic body for easy readability and chemical resistance.

- Flow Rate: Measures flow rates up to 200 liters per minute (LPM).

- Precision: High accuracy for consistent and reliable flow measurements.

- Easy Installation: Simple to install and integrate into various fermentation systems.

- Scales and Markings: Clear, easy-to-read scales for quick monitoring.

- Versatile Use: Suitable for a range of fluids used in fermentation processes.

- Compact Design: Space-saving design ideal for various setups.

- Low Maintenance: Minimal maintenance required due to robust construction.

Features:

- Material: Durable, clear acrylic body for easy readability and chemical resistance.

- Flow Rate: Measures flow rates up to 200 liters per minute (LPM).

- Precision: High accuracy for consistent and reliable flow measurements.

- Easy Installation: Simple to install and integrate into various fermentation systems.

- Scales and Markings: Clear, easy-to-read scales for quick monitoring.

- Versatile Use: Suitable for a range of fluids used in fermentation processes.

- Compact Design: Space-saving design ideal for various setups.

- Low Maintenance: Minimal maintenance required due to robust construction.

Temperature Sensor PT 100 Size 6 x 25mm Long(1/2 BSP Connection) With 3 meter PTFE Coated Cable

Ensure precise temperature control in your fermentation and pharmaceutical processes with our High-Precision PT 100 RTD Sensor. Featuring a compact size of 6 x 25mm and a 1/4 BSP connection, this sensor is designed for accurate and reliable temperature measurements. The included 3-meter PTFE coated cable and thermowell provide durability and resistance to harsh environments, making it ideal for use in demanding applications.

The High-Precision PT 100 RTD Sensor is perfect for maintaining optimal temperature conditions in fermenters used in the food and beverage industry and pharmaceutical applications. Ideal for brewing beer, making wine, and critical pharmaceutical processes, this sensor ensures accurate temperature monitoring, crucial for producing high-quality products. Its robust construction, durable cable, and included thermowell make it a reliable choice for any setup.

Application: The High-Precision PT 100 Temperature Sensor is perfect for maintaining optimal temperature conditions in fermenters used in the food and beverage industry. Ideal for brewing beer, making wine, and other fermentation processes, this sensor ensures accurate temperature monitoring, crucial for producing high-quality fermented products. Its robust construction and durable cable make it a reliable choice for any fermentation setup.

Temperature Sensor PT 100 Size 6 x 25mm Long(1/4 BSP Connection) With 3 meter PTFE Coated Cable

Application: The High-Precision PT 100 Temperature Sensor is perfect for maintaining optimal temperature conditions in fermenters used in the food and beverage industry. Ideal for brewing beer, making wine, and other fermentation processes, this sensor ensures accurate temperature monitoring, crucial for producing high-quality fermented products. Its robust construction and durable cable make it a reliable choice for any fermentation setup.

Features:

- Material: Durable, clear acrylic body for easy readability and chemical resistance.

- Flow Rate: Measures flow rates up to 30 liters per minute (LPM).

- Precision: High accuracy for consistent and reliable flow measurements.

- Easy Installation: Simple to install and integrate into various fermentation systems.

- Scales and Markings: Clear, easy-to-read scales for quick monitoring.

- Versatile Use: Suitable for a range of fluids used in fermentation processes.

- Compact Design: Space-saving design ideal for various setups.

- Low Maintenance: Minimal maintenance required due to robust construction.