Showing 1–16 of 21 resultsSorted by latest

Compact Strength for Perfect Connections – SS Hose Nipple 1/2 BSP Male (Pack of 25)

The SS Hose Nipple 1/2 BSP Male (Pack of 25 Pieces) is engineered for industries that demand durability, hygiene, and precision in every connection. Manufactured from premium stainless steel, this fitting is naturally fitted to ensure tight hose grip, leak-free performance, and long operational life. It is widely used in water lines, air pipelines, chemical transfer systems, fermenters, bioreactors, and food-grade applications where corrosion resistance is essential.

As a reliable Hose Nipple Manufacturer, we supply fittings that meet industrial standards and provide consistent quality for maintenance teams and OEM buyers. Being trusted SS 304 Hose Nipple Manufacturers and Suppliers, our products are preferred by customers across Ahmedabad, Mumbai, Pune, and Surat for their robust construction and smooth finish. Engineering units in Vadodara and fabrication workshops in Rajkot depend on these nipples for daily operations.

Industrial users from Delhi, Noida, and Ghaziabad choose this pack size for small projects and routine replacements, while process plants in Indore, Bhopal, and Ujjain value its cost-effectiveness. Whether used in pharma units in Hyderabad, food plants in Chennai, or manufacturing hubs in Bengaluru, this SS hose nipple delivers reliable performance. If you are searching for dependable hose nipple suppliers in India, this product is a smart and economical choice.

Precision That Connects Perfectly – SS Hose Nipple 1/2 BSP Male (Pack of 50)

When reliability, hygiene, and long service life matter, the SS Hose Nipple 1/2 BSP Male stands out as a naturally fitted solution for industrial and process piping systems. Manufactured using premium-grade stainless steel, this product is designed for leak-free hose connections in demanding applications such as pharmaceuticals, food processing, chemicals, dairy, breweries, fermenters, and general engineering pipelines. Supplied as a cost-effective pack of 50 pieces, it is ideal for OEMs, maintenance teams, and bulk buyers.

As a trusted Hose Nipple Manufacturer, we supply precision-machined fittings that meet international quality expectations and ensure easy installation with long-term durability. These SS 304 Hose Nipple Manufacturers and Suppliers products are corrosion-resistant and suitable for both low- and medium-pressure applications.

Our SS hose nipples are widely used by customers in Ahmedabad, Mumbai, Pune, and Surat, while also being preferred by industries in Delhi, Bengaluru, Chennai, and Hyderabad. From process plants in Vadodara to fabrication units in Rajkot, these fittings deliver consistent performance. Buyers from Indore, Bhopal, Jaipur, and Udaipur trust this product for its accuracy and finish. If you are looking for a reliable hose nipple supplier with ready stock and bulk supply capability, this product is the perfect choice.

The SS Hose Nipple 1/4 BSP x 6mm (Pack of 50 Piece) is a high-precision stainless steel fitting designed for safe, leak-free hose connections in industrial, pharmaceutical, food, and laboratory applications. Manufactured from premium SS 304 material, this hose nipple offers excellent corrosion resistance, durability, and dimensional accuracy. As a trusted Hose Nipple Manufacturer, we ensure every piece is Naturally Fitted with flexible hoses, providing a strong grip without additional sealing complications.

Industries in Ahmedabad, Mumbai, and Pune rely on these hose nipples for pneumatic and fluid transfer systems due to their consistent quality. Processing units operating in Chennai, Coimbatore, Bengaluru, and Mysuru prefer SS 304 fittings for hygienic applications. The standardized 1/4 BSP thread ensures easy installation in existing pipelines used in Hyderabad, Secunderabad, Vijayawada, and Visakhapatnam.

As reliable Hose Nipple Suppliers, we serve customers across Delhi, Gurugram, Faridabad, and Noida, offering bulk packaging for cost efficiency. Manufacturing plants in Surat, Vadodara, Rajkot, and Jamnagar trust this pack of 50 pieces for maintenance and OEM requirements. This SS hose nipple is engineered for long service life, stable performance, and secure hose connectivity across diverse industrial environments.

The SS Hose Nipple 1/4 BSP is a precision-engineered stainless steel fitting designed for secure and leak-proof hose connections in industrial, pharmaceutical, food, beverage, and chemical applications. Manufactured using high-grade stainless steel, this fitting ensures long service life, corrosion resistance, and excellent mechanical strength. As a trusted Hose Nipple Manufacturer, we focus on dimensional accuracy and superior surface finish so that the nipple is Naturally Fitted with rubber, PVC, or braided hoses without slippage.

Our products are widely preferred by Hose Nipple Suppliers serving industries across Gujarat, Maharashtra, Tamil Nadu, and Karnataka, where reliability and hygiene are critical. Designed to meet international standards, this nipple supports smooth fluid flow while maintaining pressure integrity. Industries in Rajasthan, Uttar Pradesh, Madhya Pradesh, and Haryana rely on these fittings for pneumatic and hydraulic systems.

As one of the leading SS 304 Hose Nipple Manufacturers and Suppliers, we ensure strict quality checks, making the product suitable for use in Punjab, West Bengal, Bihar, and Odisha. Whether used in refineries, laboratories, or processing plants in Telangana, Andhra Pradesh, or Kerala, this SS hose nipple offers consistent performance, durability, and ease of installation.

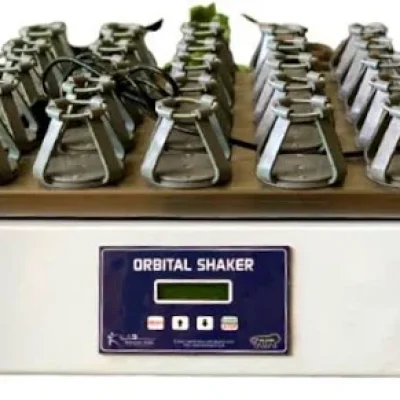

UMA PHARMATECH MACHINERY is a top-tier Laboratory Shaker Manufacturer offering precision-built Orbital Shakers and Rotary Shakers designed to hold 500ml - 16 flasks with smooth and consistent motion. Our laboratory shakers are widely used in microbiology, biotechnology, pharmaceutical, and fermentation labs for mixing, culturing, and incubation processes. As reliable Orbital Shaker Suppliers and Rotary Shaker Manufacturers, we provide robust, vibration-free equipment with adjustable speed and digital control. Trusted across research labs and industrial facilities, our laboratory shakers ensure long operational life, accurate RPM, and optimal temperature resistance, making them an ideal choice for scientific laboratories across India.

Best Orbital Shaker Manufacturer for Laboratory and Industrial Use

When research labs and industrial production units in Ahmedabad, Hyderabad, and Pune look for a trusted Orbital Shaker Manufacturer, they prioritize durability, precise speed control, and long-lasting performance. UMA PHARMATECH MACHINERY is one of the leading names in supplying premium-quality Orbital Shakers designed for laboratory research, pharmaceutical testing, and chemical mixing. Laboratories in Mumbai and Bengaluru prefer Laboratory Rotary Shaker systems that ensure smooth and consistent agitation for cell culture, microbial growth, and enzyme activity. Choosing UMA PHARMATECH MACHINERY guarantees robust performance for both small and large-volume sample mixing.

Reliable Orbital Shaker Suppliers for Pharmaceutical and Biotech Labs

In cities like Chennai, Lucknow, and Kolkata, pharmaceutical companies and biotech labs are consistently searching for reliable Orbital Shaker Suppliers to enhance their R&D activities. UMA PHARMATECH MACHINERY supplies Laboratory Rotary Shakers with advanced features like digital RPM control, timer settings, and platform customization for various flask capacities. Research centers in Gurgaon and Noida prefer UMA PHARMATECH MACHINERY for their dependable after-sales support and consistent supply of laboratory equipment. Their Orbital Shakers are suitable for bacterial culture, protein expression, and biochemical analysis in pharmaceutical and agriculture research sectors.

| · 250L Litter (Total Volume) Semi Automatic SS Fermenter · Pt-100 Temperature Sensor and Digital Temperature Controller · Semi Automatic Process Temperature Control · Air Flow Control Through Rota meter | 1 Nos |

| · SS Skid With Valves For Connecting Utilities With Fermenter(Flexible Piping From Fermenter To Skid) | 1 Nos |

| · Powder Coated Control Panel for Fermenter | 1 Nos |

| · SS 5 Inch Filter Housing With 0.2 Micron Filter Cartridge | 2 Nos |

| · Online Ph Measurement System(Sterilizable Ph. Sensor-2 to 12ph) With Digital Ph Indicator (Us Made)(Ph. Sensor + Cable + Transmitter) | 1Set |

| · Spray Ball For CIP | 1 Nos |

| · Aseptic Steam Sterilizable Sampling and Harvesting System | 1 Nos |

| Fermenter Vessel Details | ||||

| Working Volume(Litter) | 100L(Approx.) | |||

| Diameter(mm) | 400 | |||

| Straight Height(mm)(TL To TL) | 800 | |||

| shell(cylindrical) | 3 mm thk ss 316 | |||

| Jacket | 3 mm thk SS 304 | |||

| Top | Body Flange With Dish End | |||

| Bottom | Dished end( 10% torispherical) | |||

| leg | MS | |||

| Baffle Recommendation(Off Wall) | 4 Nos @ 90 Degree | |||

| manhole | No | |||

| Top Glass | 70mm(Vision 30mm) | |||

| Inner Finish | Mirror Finish | |||

| Outer finish | Matt Finish | |||

| Nozzles-Standard suitable -Tc 35mm x 19mm Connection | ||||

| Total Height | to be confirmed | |||

| Air Flow Control | Rotameter (100 LPM) | |||

| Scope of Buyer | Installation in scope of buyer (Electricity, Insulation, Water, Drain Line, Valves and Fittings and Clamp, Cooling Tower/ Overhead Tank Normal Water, Piping ) | |||

| Description | Qty | Amount(INR) |

| Advanced Configure Model | ||

| · 400 Litter (Total Volume) Semi Automatic SS Fermenter · Pt-100 Temperature Sensor and Digital Temperature Controller · Semi Automatic Process Temperature Control · Air Flow Control Through Rota meter | 1 Nos | Amount Without Tax 6 Lac /- |

| · SS Skid With Valves For Connecting Utilities With Fermenter(Flexible Piping From Fermenter To Skid) | 1 Nos | |

| · Powder Coated Control Panel for Fermenter | 1 Nos | |

| · SS 5 Inch Filter Housing With 0.2 Micron Filter Cartridge | 2 Nos | |

| · Online Ph Measurement System(Sterilizable Ph. Sensor-2 to 12ph) With Digital Ph Indicator (Us Made)(Ph. Sensor + Cable + Transmitter) | 1Set | |

| · Spray Ball For CIP | 1 Nos | |

| · Aseptic Steam Sterilizable Sampling and Harvesting System | 1 Nos | |

| · Water Chillier ((1 Tr) with 30L Inbuilt SS Tank) | 1 Nos | Extra on Demand |

| · Electric Steam Generator (All Ms Body-50 Litter Tank With Automatic Temperature Control, Automatic Pressure Control & Automatic Feed Water-24 kw) | 1 Nos | |

| · Oil Free Reciprocating Air Compressor(5 Hp- 300 LPM- On Demand By Customer) | 1 Nos | |

| Optional Automation and Sensors | ||

| · 2 No’s Peristaltic Pump For Add Acid/Alkali In Fermenter With (250ml glass Bottle + 0.2 Microns Disc Type Air Vent Filter + Silicon Tube) | 1 Set | Amount Without Tax 38000 /- |

| · Dissolve Oxygen Sensor | 1 Set | Extra on Demand |

Why Choose Uma Pharmatech Machinery?

With a strong reputation in Surat and Rajkot, we offer customized fermenters that meet the specific needs of different industries. Our bioreactor systems are equipped with stainless steel construction, automatic control panels, and efficient agitation systems, ensuring superior performance and longevity. The demand for fermenter manufacturers in Gujarat is growing, and we are at the forefront of supplying top-notch equipment.- Single phase input three phase output AC drive (VFD) with seven segment LED Digital display for speed control and direction reversal functions.

| Description | Qty | Amount(INR) |

| Double Decker Rotary Flask Shaker (5L- 50 Flask) Extended Platform Size( 1250 x 1250) Powered by continuous duty, variable speed self cooled Ac Motor with adjustable Orbital speed from 50 to 140 RPM. 5000 ml- 25 Nos – Bottom 5000 ml- 25 Nos - Top · Top Sheet Made Of Colour Coated Mild Steel Material For Flask Mounting · Base Structure Made Of Mild Steel Material Painted With Red Oxide · Motor: Ac Motor · Rotate With Eccentric Mechanism · VFD For Speed Controlling · Outer Cover Made Of Powder Coated Mild Steel Material · Fixed Eccentricity Stroke 30MM · Holding Clamp Comes With Shaker 50 Nos | 1 NOS | Amount Without Tax & Transportation |

industrial bioreactor manufacturer

1000 Litter Automatic Bioreactor System For Industrial Fermentation Plant

| Description | Technical Specification | Qty | Prize(Rs.) | ||

| 1000L( Total Volume) Fermenter(Limpet Coil)(All Tc Ball Valve) | Annexture 1 | 2 Nos | 21,00,000/-Lac | ||

| Air Pressure Control In Vessel in Process Mode | 2 Nos | ||||

| Automatic Temperature Control In Process Mode(Cooling Water Circulation & Cooling Tower is In Buyer Scope) | 2 Nos | ||||

| Speed Controlling System | 2 Nos | ||||

| SS Filter Housing Set With 0.2 MicroneSterilizable Plated Filter | 4 set | ||||

| Rotary Sprey Ball (1/2 Inch BSP) | 2 Nos | ||||

| Low Weight Movable Table(Mild Steel) For Working | 1 Nos | ||||

| Common Control Panel BOX with PLC Programming Based Control System | 1 Nos | ||||

| Skid For Connect Two Fermenter With Utility | 1 Set | ||||

| Ph Measurement System-(Sterizable Ph Electrode 120mm Long WithSS Housing+ 3 Meter Cable+ Transmitter) | 2 Set | ||||

| Peristaltic Pump (Fixed Dosing Speed)(Cmes With Glass Bottle+ PTFE Vent Filter+ 3 Meter Silicon Tube) | 2 Set | ||||

| Utilities | |||||

| Commercial Terms and Condition | |||||

| Prize Basis | Ex Factory Ahmedabad | ||||

| Packing | 1%Extra | ||||

| Freight & Insurance | By Purchase | ||||

| GST | Eatra as applicable at the time of dispatch, preseently GST 18% | ||||

| Pipe line | All Pipeline , Tubing and Electrical Work In Buyer Scope | ||||

| Installation | By customer at their site( Extra By Us After Completion Of Pipeline and Electric Work)(Free Video Calling Support) | ||||

| Payment | 60% Advance and Balance Against Proforma Invoice Before Dispatch | ||||

| Annexture 1 | |||||

| Fermenter Vessel Details | |||||

| Total Volume(Litter) | 1000L | ||||

| Diameter(mm) | 850 | ||||

| Straight Height(mm) | 1630 | ||||

| shell(cylindrical) | 5 mm thk ss 316 | ||||

| Limpet Coil on Shell, Single Start | 50 NB @90 Pitch 3mm Thickness-SS304 | ||||

| Top | Body Flange | ||||

| Bottom | Dished end( 10% torispherical) | ||||

| leg | mild steel | ||||

| Baffle Recommendation(Off Wall) | 4 Nos @ 90 Degree | ||||

| manhole | No | ||||

| Top Glass | 100mm(Vision 50mm) | ||||

| Front Glasas | 100mm(Vision 50mm) | ||||

| Inner Finish | Mirror Finish | ||||

| Outer finish | Matt Finish | ||||

| Nozzles-Standard suitable - Nipple | |||||

| Total Height | to be confirmed | ||||

| Design Criteria | |||||

| Viscosity | 100 cP | SG | 1.1 | ||

| Pressure | FV to 3kg/cm2 | Temp | 130 deg C | ||

| Mechanical Detail | |||||

| Sealing | Mechanical Seal | ||||

| Gearbox (Elmech) | Worm Gearbox | ||||

| Motor HP (Elmech) | 3 | NFLP, 4 Pole, Flanged, 3 Ph, 415 V, 50 Hz, | |||

| Impeller Type (From bottom) | Ruston Turbine | Ruston Turbine | Ruston Turbine | ||

| Impeller Blade | 6 Blade | 6 Blade | 6 Blade | ||

| Agitator Details | |||||

| MOC Contact Parts | SS 316 | Shaft Diameter | 50 mm | ||

| MOC Non-CP | MS/CS | Shaft Speed(RPM) | 144 | ||

| Air Flow Control | Rotameter(100 LPM) | Speed Controlling | VFD | ||

| Scope of Supply | Design, manufactur, supply of UPM make agitator assembly. Which includes impeller blades with hub, shaft, lantern assembly with bearing housing etc. | ||||

| Scope of Buyer | Installation in scope of buyer (Electricity,Insulation, Water, Drain Line, Valves and Fittings and Clamp ) | ||||

| General @ Technical Terms and Condition | |||||

| FORCE MAJEURE Every effort will be made to deliver the goods within stipulated delivery period, but we take no responsibility for any delay occasioned by reasons beyond our control, known as ‘Force Majeure’. Delayed delivery will not entitle the customer for cancellation of contract. No claim for refund of deposits / advance or damages will be entertained in such cases. | |||||

| JURISDICTION Irrespective of where the material goes or what is mentioned in the purchase order, disputes, if any, shall be subject to Pune jurisdiction only. | |||||

| WARRANTY We warranty the instruments against only manufacturing defects during 12 months from date of sale subject to our detailed warranty terms & conditions sent with the material. No other Guarantee / Warranty will be binding on us. Under no circumstances we will be responsible to anybody for any type of consequential liability/ loss of public property/ loss of life due to any reasons whatsoever i.e. public/ product is not within the purview of this warranty The warranty does not cover perishable items like pH / ION / DO / Chlorine / Conductivity &other Sensors, all semiconductor devices, Fuse, Transistor, Electrical / Mechanical/ Rubber Parts like Electric Motors, Switches, Contactors, Thermostats, Heaters, Diaphragms, “O” Ring, etc., Thruster Module, Batteries, PZT Crystals, etc & other imported components etc. The Performance of the Sensor / Electrode will be drastically affected if integral cable is cut or damaged. Guarantee / Manufacturing defect clause is not applicable in such case.The Performance / Life of pH Electrode/ Sensor will get affected by presence of HF, Solvents, and Aromatic compounds, Highly Acidic / Alkaline Medium. We will not be responsible for Electronic Goods/ Heater/ Controllers/ Motors/ Panel Board Electrical goods and any accident or damage caused by improper handling, misuse or non-maintenance of the machine or accessories. No Warranty for Movable items as they are subjected to wear and tear due to usage and operator’s handling. No claim for Shortage, Damage, Breakage etc., will be entertained after the goods leave our permises. | |||||

| REJECTION CLAUSE: If you’re good self / representative fails to arrive for Final Inspection, then it will be considered that the offered machine perfectly fits in with your needs and is devoid of any manufacturing regards ever in future. Machine / goods once sold would not be taken back. . Any laboratory equipments in customer’s scope of supply.. All statutory approvals to be obtained by customer. Any other items which are not mentioned in our offer is in customers’ scope. | |||||

| DEMURRAGE CHARGES: Any delay from the client’s end in depositing Balance Payment after machine readiness information is passed onto him, then in such scenario we will charge 2% demurrage charges per month on the balance amount. | |||||

| ERECTION & COMMISSIONING: If required, then technician’s service charges, to and fro ticket charges, plus lodging / boarding charges will be charged extra. Main Switch, Starter and extension wirings for electric motor are not provided with the Order. All Spare Parts can be made available on chargeable basis, whenever required. Dispatch charges Extra. |