Shop and Save Big on Hottest Products

Don't miss this special opportunity today.

Showing all 12 resultsSorted by latest

Stainless Steel Roundbar Distribution for Ahmedabad’s Key Industries

In dynamic industrial regions like Changodar and Odhav, the importance of a dependable SS Roundbar Distributor in Ahmedabad becomes clear. Manufacturers dealing with textile machinery, process equipment, and food processing components depend heavily on accurate diameters, straightness, and polished finishes. These distributors not only supply material but also provide value-added services such as cutting, bending, and test certification as per industry standards.

Meanwhile, engineering companies located in Santej GIDC prefer buying in bulk from a trusted SS Roundbar Wholesaler in Ahmedabad who can offer competitive prices and wide stock availability. For high-volume orders and repeat procurement, having a wholesale partner with brands like Jindal Steel and JSW becomes a game-changer.

Our SS 316 Round Bars are manufactured from high-quality stainless steel, offering excellent corrosion resistance and strength. These bars are widely used in industries such as chemical processing, marine, and food processing. Available in various sizes and finishes to meet specific requirements.

Tc End Diaphragm Valve SS316( Imported)

- Fermenters: Ensure precise flow control to optimize fermentation processes in the food and beverage industry.

- Bioreactors: Provide accurate flow regulation for biological reactions in biotech and pharmaceutical manufacturing.

- Chemical Processing: Deliver reliable flow control for various chemical reactions and processes.

- Biofertilizer Production: Optimize production environments with precise flow regulation.

- Pharmaceutical Manufacturing: Ensure safe and consistent flow control in pharmaceutical production processes.

- Dairy Processing: Maintain optimal flow conditions for various dairy processing applications.

- Biotech Operations: Support a wide range of biotech processes with reliable flow control and regulation.

3 Way TC End Ball Valve SS 316

Application

- Fermenters: Ideal for use in homebrewing and professional brewing fermenters.

- Brewing Systems: Perfect for controlling fluid flow in complex brewing systems.

- Food & Beverage Industry: Suitable for various sanitary fluid control applications.

- Laboratories: Great for precise control of fluids in laboratory setups.

High-Quality 3 Way TC End Ball Valve SS 304

Application

- Fermenters: Ideal for use in homebrewing and professional brewing fermenters.

- Brewing Systems: Perfect for controlling fluid flow in complex brewing systems.

- Food & Beverage Industry: Suitable for various sanitary fluid control applications.

- Laboratories: Great for precise control of fluids in laboratory setups.

Tc End Diaphragm Valve SS304( Imported)

- Fermenters: Ensure precise flow control to optimize fermentation processes in the food and beverage industry.

- Bioreactors: Provide accurate flow regulation for biological reactions in biotech and pharmaceutical manufacturing.

- Chemical Processing: Deliver reliable flow control for various chemical reactions and processes.

- Biofertilizer Production: Optimize production environments with precise flow regulation.

- Pharmaceutical Manufacturing: Ensure safe and consistent flow control in pharmaceutical production processes.

- Dairy Processing: Maintain optimal flow conditions for various dairy processing applications.

- Biotech Operations: Support a wide range of biotech processes with reliable flow control and regulation.

Tc End Ball Valve SS304

- Fermenters: Ensure precise flow control to optimize fermentation processes in the food and beverage industry.

- Bioreactors: Provide accurate flow regulation for biological reactions in biotech and pharmaceutical manufacturing.

- Chemical Processing: Deliver reliable flow control for various chemical reactions and processes.

- Biofertilizer Production: Optimize production environments with precise flow regulation.

- Pharmaceutical Manufacturing: Ensure safe and consistent flow control in pharmaceutical production processes.

- Dairy Processing: Maintain optimal flow conditions for various dairy processing applications.

- Biotech Operations: Support a wide range of biotech processes with reliable flow control and regulation.

Tc End Ball Valve SS316

- Fermenters: Ensure precise flow control for optimal fermentation processes in the food and beverage industry.

- Bioreactors: Provide accurate flow regulation for biological reactions in biotech and pharmaceutical manufacturing.

- Chemical Processing: Deliver reliable flow control for chemical reactions and processes.

- Biofertilizer Production: Optimize production environments with accurate flow regulation.

- Pharmaceutical Manufacturing: Ensure safe and consistent flow control in pharmaceutical production processes.

- Dairy Processing: Maintain optimal flow conditions for various dairy processing applications.

- Biotech Operations: Support a wide range of biotech processes with reliable flow control and regulation.

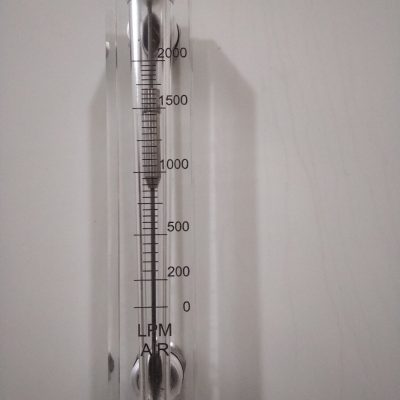

- Material: Durable, clear acrylic body for easy readability and chemical resistance.

- Flow Rate: Measures flow rates up to 2000 liters per minute (LPM).

- Precision: High accuracy for consistent and reliable flow measurements.

- Easy Installation: Simple to install and integrate into various fermentation systems.

- Scales and Markings: Clear, easy-to-read scales for quick monitoring.

- Versatile Use: Suitable for a range of fluids used in fermentation processes.

- Compact Design: Space-saving design ideal for various setups.

- Low Maintenance: Minimal maintenance required due to robust construction.

- Material: Durable, clear acrylic body for easy readability and chemical resistance.

- Flow Rate: Measures flow rates up to 1000 liters per minute (LPM).

- Precision: High accuracy for consistent and reliable flow measurements.

- Easy Installation: Simple to install and integrate into various fermentation systems.

- Scales and Markings: Clear, easy-to-read scales for quick monitoring.

- Versatile Use: Suitable for a range of fluids used in fermentation processes.

- Compact Design: Space-saving design ideal for various setups.

- Low Maintenance: Minimal maintenance required due to robust construction.

- Material: Durable, clear acrylic body for easy readability and chemical resistance.

- Flow Rate: Measures flow rates up to 200 liters per minute (LPM).

- Precision: High accuracy for consistent and reliable flow measurements.

- Easy Installation: Simple to install and integrate into various fermentation systems.

- Scales and Markings: Clear, easy-to-read scales for quick monitoring.

- Versatile Use: Suitable for a range of fluids used in fermentation processes.

- Compact Design: Space-saving design ideal for various setups.

- Low Maintenance: Minimal maintenance required due to robust construction.

- Material: Durable, clear acrylic body for easy readability and chemical resistance.

- Flow Rate: Measures flow rates up to 200 liters per minute (LPM).

- Precision: High accuracy for consistent and reliable flow measurements.

- Easy Installation: Simple to install and integrate into various fermentation systems.

- Scales and Markings: Clear, easy-to-read scales for quick monitoring.

- Versatile Use: Suitable for a range of fluids used in fermentation processes.

- Compact Design: Space-saving design ideal for various setups.

- Low Maintenance: Minimal maintenance required due to robust construction.

- Material: Durable, clear acrylic body for easy readability and chemical resistance.

- Flow Rate: Measures flow rates up to 30 liters per minute (LPM).

- Precision: High accuracy for consistent and reliable flow measurements.

- Easy Installation: Simple to install and integrate into various fermentation systems.

- Scales and Markings: Clear, easy-to-read scales for quick monitoring.

- Versatile Use: Suitable for a range of fluids used in fermentation processes.

- Compact Design: Space-saving design ideal for various setups.

- Low Maintenance: Minimal maintenance required due to robust construction.