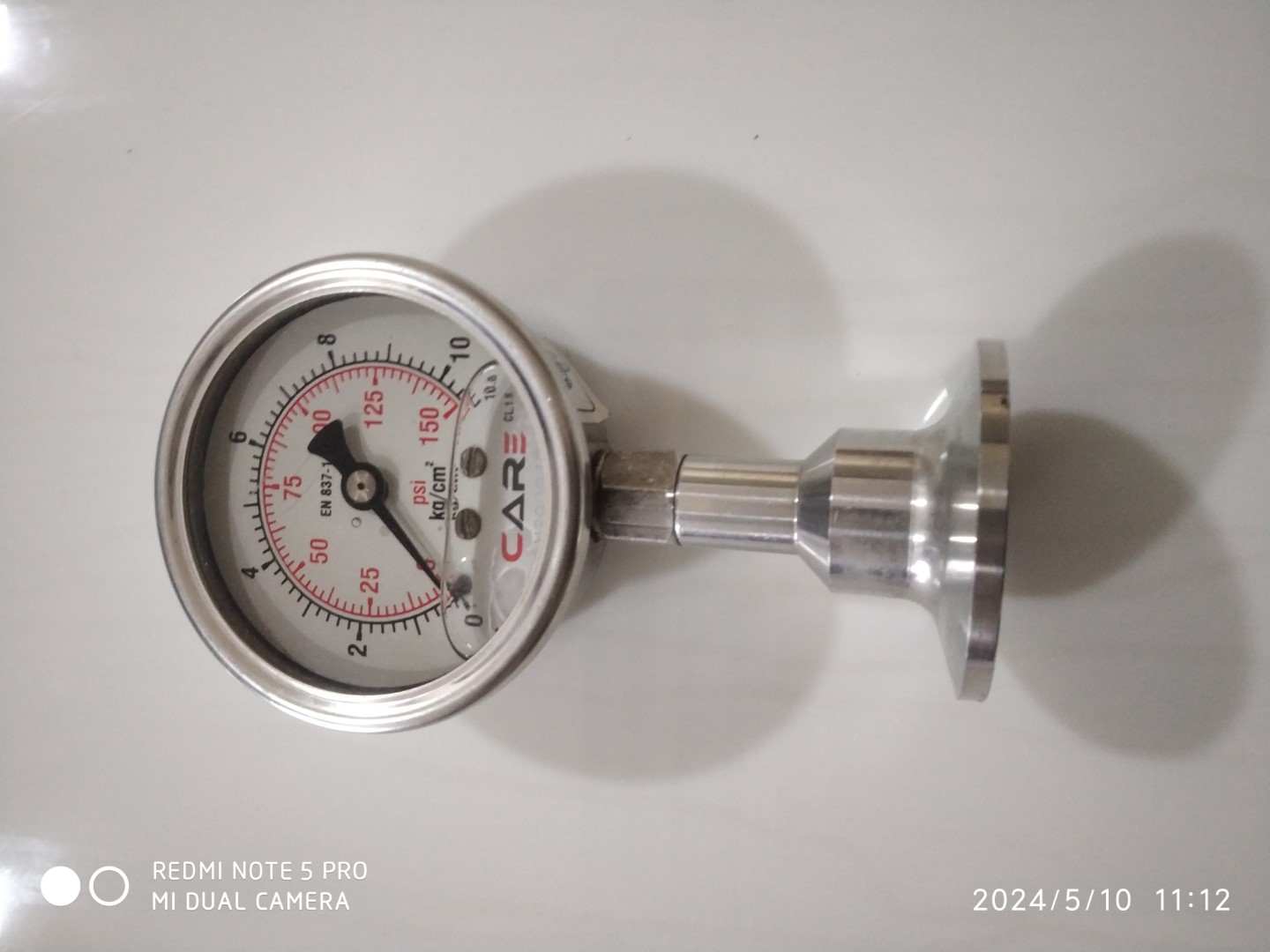

SS Diaphragm Type Pressure Gauge(Dial 2.5 Inch)(10 Bar)

SS Diaphragm Type Pressure Gauge(Dial 2.5 Inch)(10 Bar)

Introducing our top-of-the-line Gel-Filled Stainless Steel Diaphragm Type Pressure Gauge, specifically designed for fermenters. Engineered for precision and durability, this pressure gauge ensures accurate readings and long-lasting performance in demanding environments. The gel-filled diaphragm provides superior protection against vibration and pulsation, making it ideal for maintaining optimal pressure levels in your fermentation processes.

Description

SS Diaphragm Type Pressure Gauge(Dial 2.5 Inch)(10 Bar)

Application: Our Gel-Filled Stainless Steel Diaphragm Type Pressure Gauge is perfect for use in fermentation processes within the food and beverage industry. Whether you’re brewing beer, making wine, or producing other fermented products, this gauge ensures precise monitoring and control of pressure levels, crucial for maintaining product quality and consistency.

#PressureGauge #StainlessSteelGauge #GelFilledGauge #DiaphragmPressureGauge #FermentationEquipment #BrewingGear #WinemakingTools #IndustrialPressureGauge #AccurateMeasurement #DurableEquipment #HygienicDesign #FermenterTools

Related products

- Material: Constructed from polypropylene (PP) for superior chemical resistance and longevity.

- Filtration Efficiency: 0.2-micron pore size effectively filters out bacteria and other particulates.

- Size: 10-inch length provides extended filtration capacity and efficiency.

- Code 7 Connection: Ensures a secure and leak-free fit with compatible housings.

- High Flow Rate: Allows efficient air exchange while maintaining stringent filtration standards.

- Durable Construction: Robust design suitable for continuous use in industrial environments.

- Easy Installation: Compatible with standard Code 7 filter housings for straightforward integration.

- Cost-Effective: Long-lasting and reliable, minimizing the need for frequent replacements.

- Single phase input three phase output AC drive (VFD) with seven segment LED Digital display for speed control and direction reversal functions.

- Material: Durable, clear acrylic body for easy readability and chemical resistance.

- Flow Rate: Measures flow rates up to 1000 liters per minute (LPM).

- Precision: High accuracy for consistent and reliable flow measurements.

- Easy Installation: Simple to install and integrate into various fermentation systems.

- Scales and Markings: Clear, easy-to-read scales for quick monitoring.

- Versatile Use: Suitable for a range of fluids used in fermentation processes.

- Compact Design: Space-saving design ideal for various setups.

- Low Maintenance: Minimal maintenance required due to robust construction.

Reviews

There are no reviews yet.