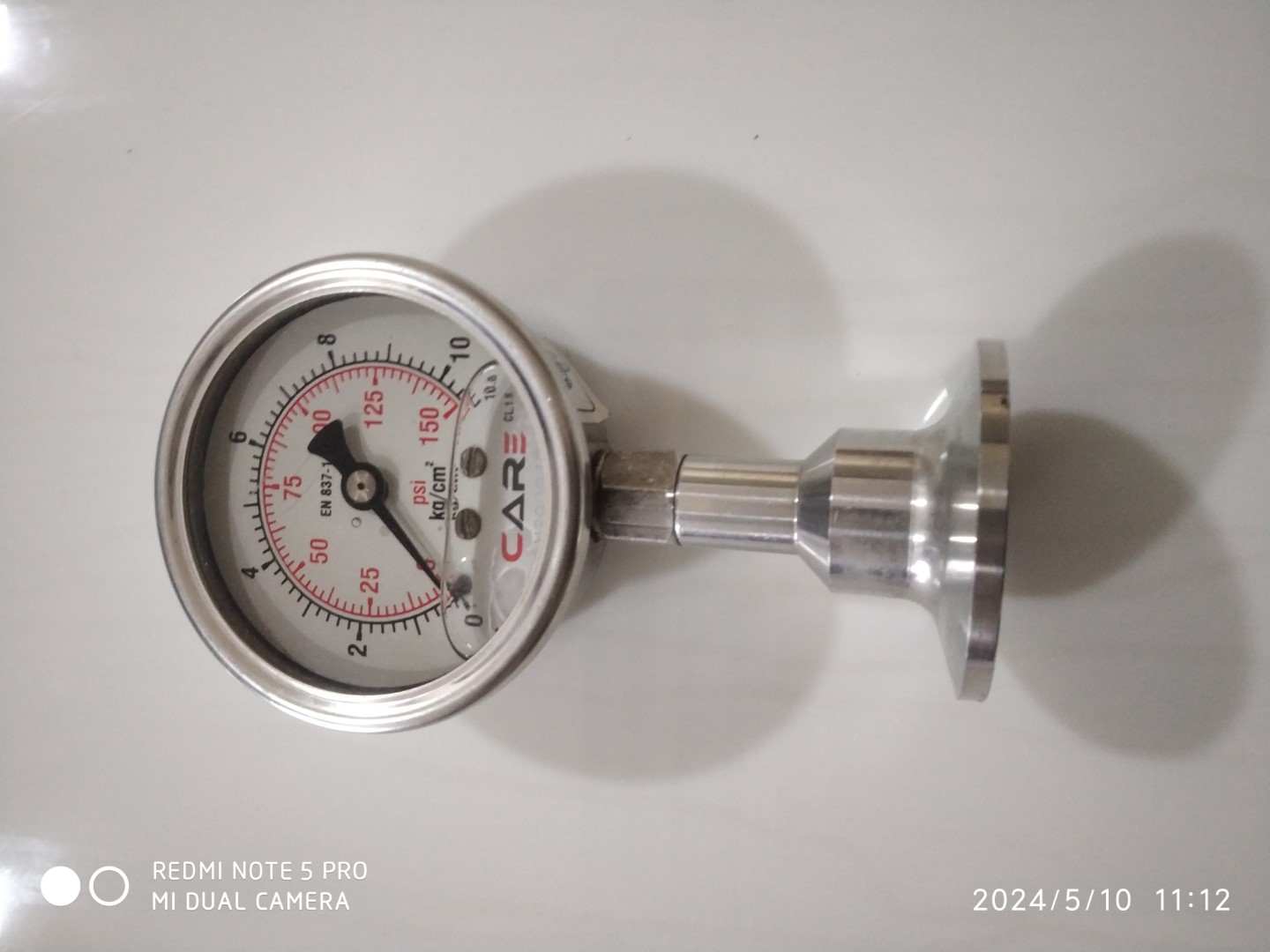

SS Diaphragm Type Pressure Gauge(Dial 2.5 Inch)(10 Bar)

SS Diaphragm Type Pressure Gauge(Dial 2.5 Inch)(10 Bar)

Introducing our top-of-the-line Gel-Filled Stainless Steel Diaphragm Type Pressure Gauge, specifically designed for fermenters. Engineered for precision and durability, this pressure gauge ensures accurate readings and long-lasting performance in demanding environments. The gel-filled diaphragm provides superior protection against vibration and pulsation, making it ideal for maintaining optimal pressure levels in your fermentation processes.

Description

SS Diaphragm Type Pressure Gauge(Dial 2.5 Inch)(10 Bar)

Application: Our Gel-Filled Stainless Steel Diaphragm Type Pressure Gauge is perfect for use in fermentation processes within the food and beverage industry. Whether you’re brewing beer, making wine, or producing other fermented products, this gauge ensures precise monitoring and control of pressure levels, crucial for maintaining product quality and consistency.

#PressureGauge #StainlessSteelGauge #GelFilledGauge #DiaphragmPressureGauge #FermentationEquipment #BrewingGear #WinemakingTools #IndustrialPressureGauge #AccurateMeasurement #DurableEquipment #HygienicDesign #FermenterTools

Related products

- Fermenters: Ensure precise pH control to optimize fermentation processes in the food and beverage industry.

- Bioreactors: Provide accurate pH monitoring for biological reactions in biotech and pharmaceutical manufacturing.

- Chemical Processing: Deliver reliable pH measurement for various chemical reactions and processes.

- Biofertilizer Production: Optimize production environments with precise pH regulation.

- Pharmaceutical Manufacturing: Ensure safe and consistent pH levels in pharmaceutical production processes.

- Dairy Processing: Maintain optimal pH conditions for various dairy processing applications.

- Biotech Operations: Support a wide range of biotech processes with reliable pH monitoring and control.

- Fermenters: Maintain precise pressure control for optimal fermentation processes in the food and beverage industry.

- Bioreactors: Ensure accurate pressure monitoring for biological reactions in biotech and pharmaceutical manufacturing.

- Chemical Processing: Provide reliable pressure control for chemical reactions and processes.

- Biofertilizer Production: Optimize the production environment with accurate pressure regulation.

- Pharmaceutical Manufacturing: Ensure safe and consistent pressure levels in pharmaceutical production processes.

- Dairy Processing: Maintain optimal pressure conditions for various dairy processing applications.

- Biotech Operations: Support a wide range of biotech processes with reliable pressure monitoring and control.

Reviews

There are no reviews yet.