No products in the cart.

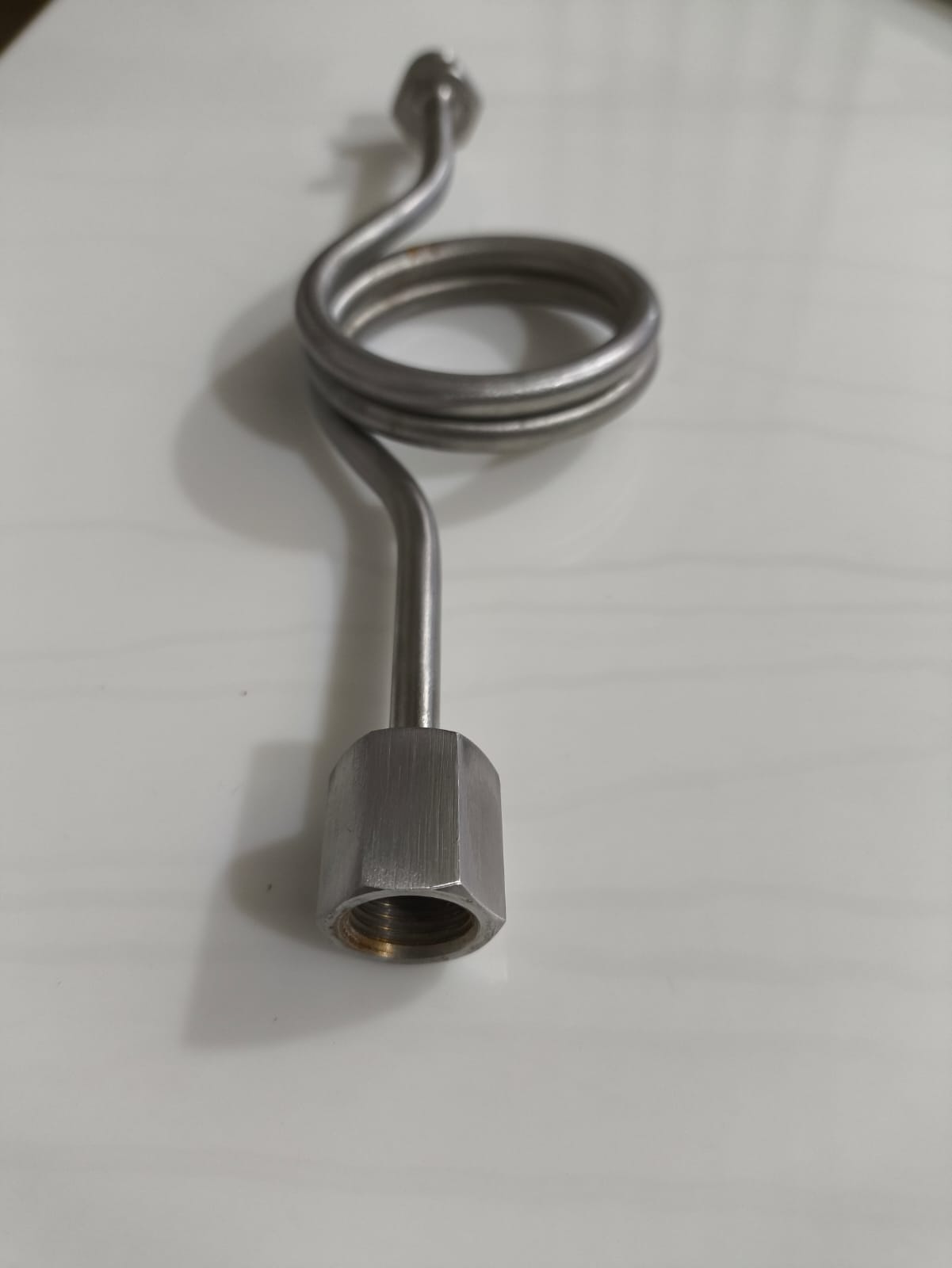

ss Syphon Double Q , Size: 1/4 BSP

In Stock

In Stock

Category: Process Instruments

Tags: Q Syphone, ss Syphone, Syphone 1/4 BSP Male Female

ss Syphone Double Q , Size: 1/4 BSP

Connection: 1/4 BSP Male x 1/4 BSP Female

Description

ss Syphon Double Q , Size: 1/4 BSP

Connection: 1/4 BSP Male x 1/4 BSP Female

Be the first to review “ss Syphon Double Q , Size: 1/4 BSP” Cancel reply

Related products

Application: The Sterializable pH Sensor with Controller is perfect for maintaining optimal pH levels in various industrial applications, including:

- Fermenters: Ensure precise pH control to optimize fermentation processes in the food and beverage industry.

- Bioreactors: Provide accurate pH monitoring for biological reactions in biotech and pharmaceutical manufacturing.

- Chemical Processing: Deliver reliable pH measurement for various chemical reactions and processes.

- Biofertilizer Production: Optimize production environments with precise pH regulation.

- Pharmaceutical Manufacturing: Ensure safe and consistent pH levels in pharmaceutical production processes.

- Dairy Processing: Maintain optimal pH conditions for various dairy processing applications.

- Biotech Operations: Support a wide range of biotech processes with reliable pH monitoring and control.

Temperature Sensor PT 100 Size 6 x 25mm Long(1/2 BSP Connection) With 3 meter PTFE Coated Cable

Ensure precise temperature control in your fermentation and pharmaceutical processes with our High-Precision PT 100 RTD Sensor. Featuring a compact size of 6 x 25mm and a 1/4 BSP connection, this sensor is designed for accurate and reliable temperature measurements. The included 3-meter PTFE coated cable and thermowell provide durability and resistance to harsh environments, making it ideal for use in demanding applications.

The High-Precision PT 100 RTD Sensor is perfect for maintaining optimal temperature conditions in fermenters used in the food and beverage industry and pharmaceutical applications. Ideal for brewing beer, making wine, and critical pharmaceutical processes, this sensor ensures accurate temperature monitoring, crucial for producing high-quality products. Its robust construction, durable cable, and included thermowell make it a reliable choice for any setup.

Application: The High-Precision PT 100 Temperature Sensor is perfect for maintaining optimal temperature conditions in fermenters used in the food and beverage industry. Ideal for brewing beer, making wine, and other fermentation processes, this sensor ensures accurate temperature monitoring, crucial for producing high-quality fermented products. Its robust construction and durable cable make it a reliable choice for any fermentation setup.

Features:

- Material: Durable, clear acrylic body for easy readability and chemical resistance.

- Flow Rate: Measures flow rates up to 1000 liters per minute (LPM).

- Precision: High accuracy for consistent and reliable flow measurements.

- Easy Installation: Simple to install and integrate into various fermentation systems.

- Scales and Markings: Clear, easy-to-read scales for quick monitoring.

- Versatile Use: Suitable for a range of fluids used in fermentation processes.

- Compact Design: Space-saving design ideal for various setups.

- Low Maintenance: Minimal maintenance required due to robust construction.

Application: The Denforce KP 35 Diaphragm Type Pressure Switch is ideal for use in a broad range of industrial applications, including:

- Fermenters: Maintain precise pressure control for optimal fermentation processes in the food and beverage industry.

- Bioreactors: Ensure accurate pressure monitoring for biological reactions in biotech and pharmaceutical manufacturing.

- Chemical Processing: Provide reliable pressure control for chemical reactions and processes.

- Biofertilizer Production: Optimize the production environment with accurate pressure regulation.

- Pharmaceutical Manufacturing: Ensure safe and consistent pressure levels in pharmaceutical production processes.

- Dairy Processing: Maintain optimal pressure conditions for various dairy processing applications.

- Biotech Operations: Support a wide range of biotech processes with reliable pressure monitoring and control.

Specifications

No. of Channels : One , speed : 20 to 200 RPM, Flow rate : 1.6 to 16 Lit/min

Tubing : 20 mm I.D. with 4 mm wall thickness

End Connection : 3/4” TC(Tc 50mm)

M.O.C. of the Pump Head

Outer ARM : Anodized Aluminum

ARM Cover : Transparent Polycarbonate

Rotor : S.S.304

Rollers : Carbon filled Nylon

Enclosure : S.S.304

Motor : 3 phase, 0.5 H.P. geared AC motor

Differential Pressure : Up to 2 Kg/Sq.cm Supply : 230v, 50Hz, Single phase AC supply, 370 Watt

Dimension : 240 x 400 x 620 mm (H x W x D)

Weight : 25 Kgs .(Approx.)

Controls

- Single phase input three phase output AC drive (VFD) with seven segment LED Digital display for speed control and direction reversal functions.

Features:

- Material: Durable, clear acrylic body for easy readability and chemical resistance.

- Flow Rate: Measures flow rates up to 200 liters per minute (LPM).

- Precision: High accuracy for consistent and reliable flow measurements.

- Easy Installation: Simple to install and integrate into various fermentation systems.

- Scales and Markings: Clear, easy-to-read scales for quick monitoring.

- Versatile Use: Suitable for a range of fluids used in fermentation processes.

- Compact Design: Space-saving design ideal for various setups.

- Low Maintenance: Minimal maintenance required due to robust construction.

Reviews

There are no reviews yet.